LIGHTFASTNESS

The pigments used have reasonable lightfastness, but may not be suitable

for extended exposure to direct sunlight.

This property can be built in if specified when ordering.

RESISTANCE PROPERTIESA number of resistance properties of the

print, e.g., heat, scuff, slip, soap jelly – may be required. These

properties

are built in within AL STAR range and need to be specified when

ordering.

SAFETY REGULATIONS

Material safety data sheet is separately available.

MAC AL STAR INK

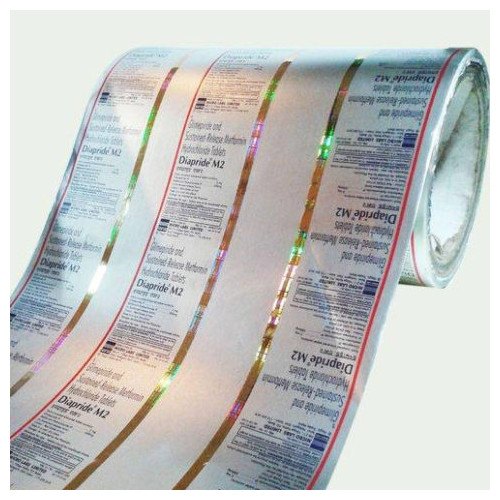

MAC AL STAR Inks are Nitrocellulose based Gravure inks and recommended to be used for printing Foil , Paper and Paper Board, used for packaging and pharma related applications. AL STAR inks with specific properties are available to meet the desired resistance properties ... As per end use requirements of a particular job, the desired level of the print properties should be discussed with MAC Technical Service personnel. Salient features are :

- Good gloss and press stability

- Acceptable Fold and Rub resistance

- Excellent resolubility

- Good printability

- Stable rheology during printing

- Excellent reproduction of halftone even at high speed.

- Good solvent release , quick drying and excellent block resistance.

- Low solvent Retention

SUBSTRATE

All varieties of papers and boards Foils could be printed with AL STAR inks.

Print quality depends on grade of

Surface and press conditions. In case of Aluminium Foils , its surface has to be

primed ( off line) before it subjected

to printing .To have enhanced gloss and scratch resistance overcoat is required.

WASH UP

Mixture of Ethyl Alcohol and Ethyl Acetate is used most to thin down AL STAR

inks. To make the ink drying faster,

higher percentage of Ethyl Acetate is recommended. The retarder is Ethoxy

Propanol /Diacetone Alcohol.

COLOUR RANGE

A full range of colours are available. Specific shades are matched on

demand.

Request for a Quote

Contact Us